Motor Starting Auto Transformer

During start up, large squirrel cage motors and synchronous motors have the undesirable characteristic of drawing up to 6 or 8 times normal running current from the power source. This start up current is at its peak the moment that power is applied and gradually diminishes to load running current as the motor reaches normal speed. Substantial voltage drop on the feeder lines is often the result and it may be severe enough to cause contactors to drop out, light flickering and malfunction of other electrical or electronic equipment connected to the feeder lines.

Full voltage starting is the least expensive way to start a motor. However, due to utility company regulations or voltage drop problems, it is often necessary to employ a modified starting system that will reduce the motor starting inrush current. Also some driven machinery requires a reduced starting torque to cusion the application of mechanical power to the driven load. The most commonly used modified starting system is the auto transformer reduced voltage starter.

VICTOR’s MSAT Series is recommended for AC Motor applications that require reduced voltage starting. It is designed for use with either magnetic or manually operated motor controllers.

The MSAT’s primary function is to limit inrush current and starting torque in AC motors under starting or locked rotor conditions. This eliminates the problems associated with line voltage drop, resulting from high inrush currents

Motor Starting Auto Transformers are designed to meet medium duty service. This includes motor applications for driving fans, pumps, compressors, line shafts, etc. Note that these standards are applicable where the windings are in the circuit only during starting.

Features:

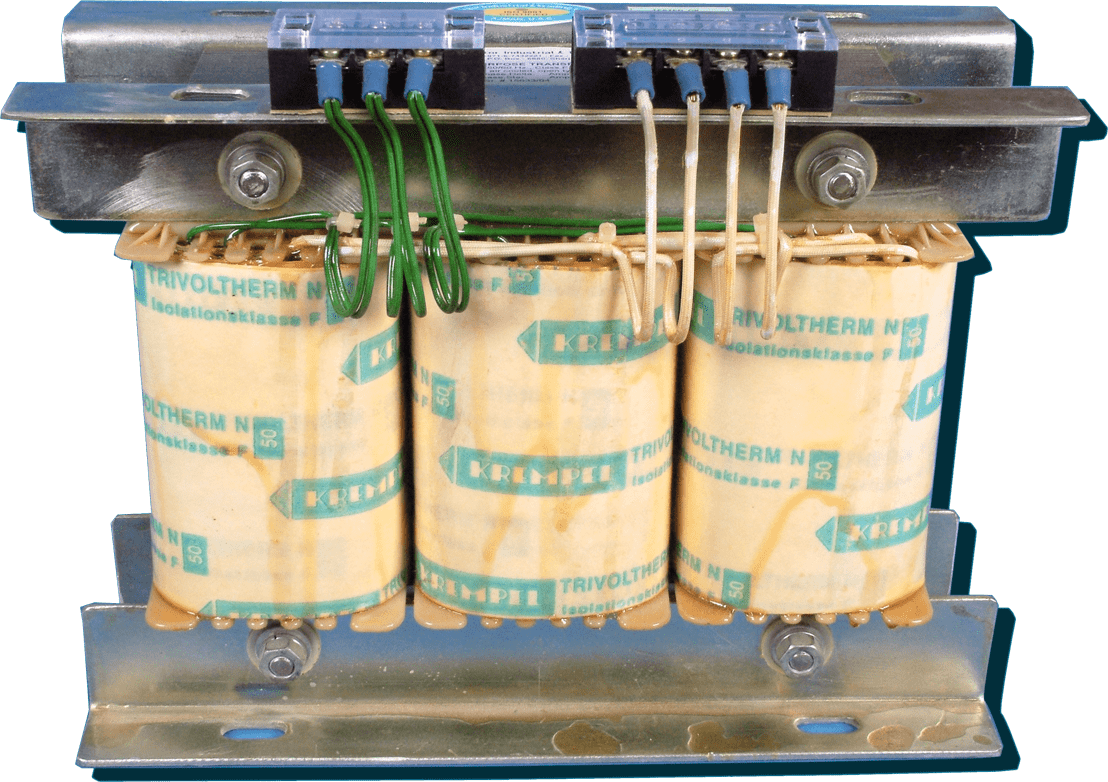

- Open Frame construction

- Three Coil Design, Three Phase, 50/60 Hz.

- Class F Insulation

- Standard taps @ 50 – 65 – 85 – 100% of Nominal Line Voltage. Other taps as specified by the customer

SIZE RANGE (HP):

5, 7.5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 125, 150, 200, 300, 400

Normal Motor Voltages

- 190/220/240/380/415/440/460/480/575 Volts Nominal. 3 Phase, 50/60 Hz, 600 Volts Class, Dry Type Taps at 50%, 65%, 85% and 100% Nominal Line voltage Three Coil, Open Frame Construction

Sequence of Operations:

- Contact 1S is close giving star point for the auto transformers

- Contacts 2S close for getting auto transformer ready and giving reduced supply to the motor at selected Tap (65% in example) and now the motor accelerates.

- After some time delay contact 1S is open, now the star point is removed and the motor runs with the top portion of the auto transformer and in series with motor winding.

- After some delay contacts R close thereby shorting the top portion of the Auto Transformer winding and giving supply to the motor directly.

- Now the contact 1S is open there by completely removing the Auto Transformer from supply.