General Purpose Transformers

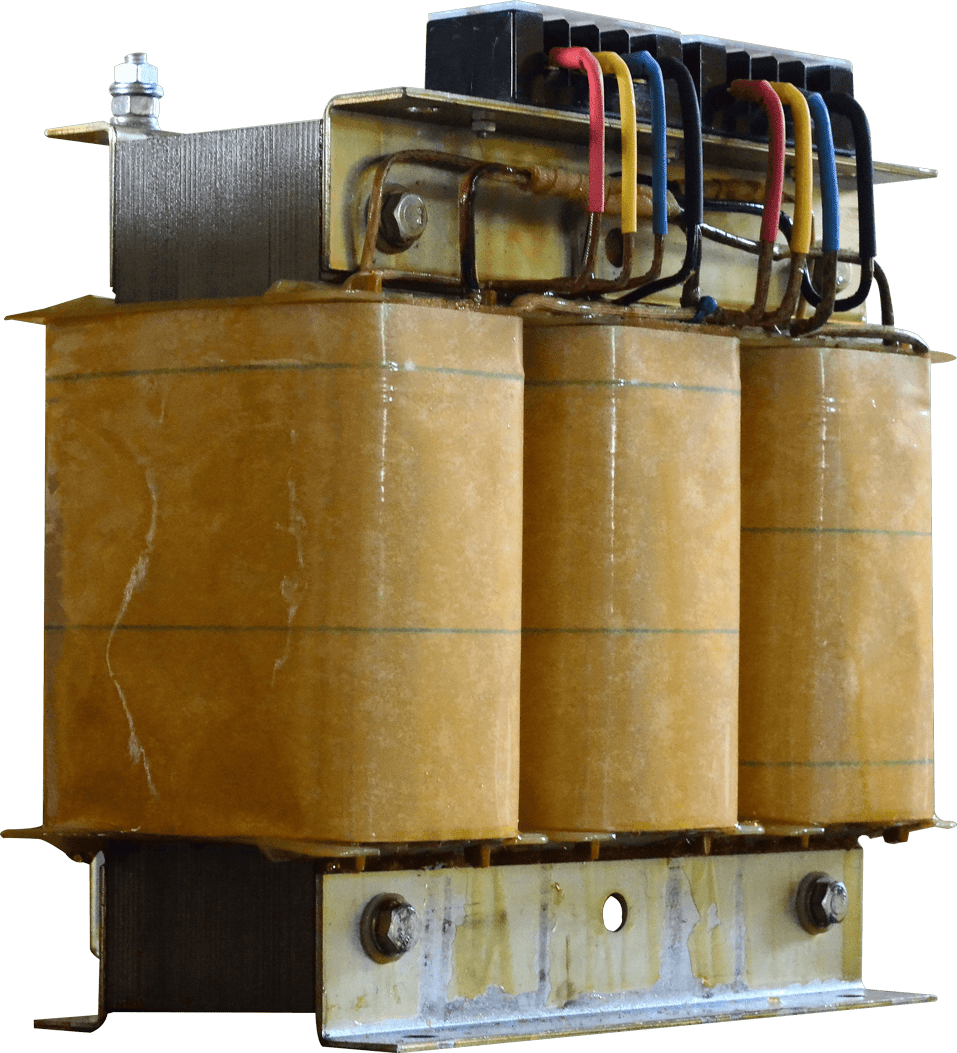

All general purpose transformers rated 15 KVA and below, utilize a non-oriented, fully processed, silicon electrical steel having a superior permeability at high induction, low average losses, with a high resistance insulation formed by a chemical treatment. All general purpose transformers rated 20 KVA and larger utilize the finest grades of grain oriented silicon steel enabling the transformer to be made compact, efficient, and economical, without compromising electrical performance. Extreme care is taken in hand stacking of the lamination cores, on a special steel frame specifically adjusted for the transformer being assembled.Core laminations are stacked, carefully aligned, firmly clamped with special steel channel, then varnished and baked until the varnish sets. This gives the cores additional mechanical strength and seals it against moisture, to insure that the complete transformer will have minimum losses and will operate quietly

Coil Construction

All (GPT) general purpose transformers utilize copper magnet conductors. Copper has been proven over the years to be the best material for this purpose. The coils are wound with class F as a standard feature. All general purpose transformers rated 20 KVA and larger utilize fiber strip coil spacers, forming a duct in the coil. This method of coil construction permits the flow of a larger volume of air in the coil, providing a cooler operation under all load conditions.

Impregnation and Tropicalization

The purpose of impregnation is to replace the air in the coil by an insulating varnish. This keeps moisture out.Tropicalization, is performed on request, for use under excessively harsh climate of moisture condition, consists of:

- Additional protection of the lamination core.

- A fungicidal treatment (varnish)

- A thick coat of epoxy resin.

Enclosure and Mounting Frame

All Victor transformer enclosures are fabricated from a drip proof 2 mm electro-zinc coated steel. The enclosure will have knockouts on both sides for input and output cable entrance or gland plate at bottom for cable entry. Front, top, and rear cover panels are removable for easy access to terminal compartment. Enclosure is provided with lifting facilities without removal of any of the enclosure component. Mounting frames are designed as such, that the core and coil assembly is supported on two angle brackets which are bolted to the sides of the enclosure. The enclosure is provided by full width air recirculation vents at top of case with rodent proof expanded steel at the bottom; this ventilated design provides free air flow from the bottom, conducting the heat out.

Features:

- Designed for lower weight and smaller size for easier installation and handling.

- Heavy duty sheet Metal enclosures for better durability in severe industrial applications.

- Large connection compartment for ease of wiring and installation.

- Heat applied gray powder coat finish to resist corrosion in industrial environments.

- Core made from high quality electrical steel for increased efficiency and lower operating costs.

- 180 deg. C insulation system standard with 115 deg. C temperature rise for longer, more reliable life.

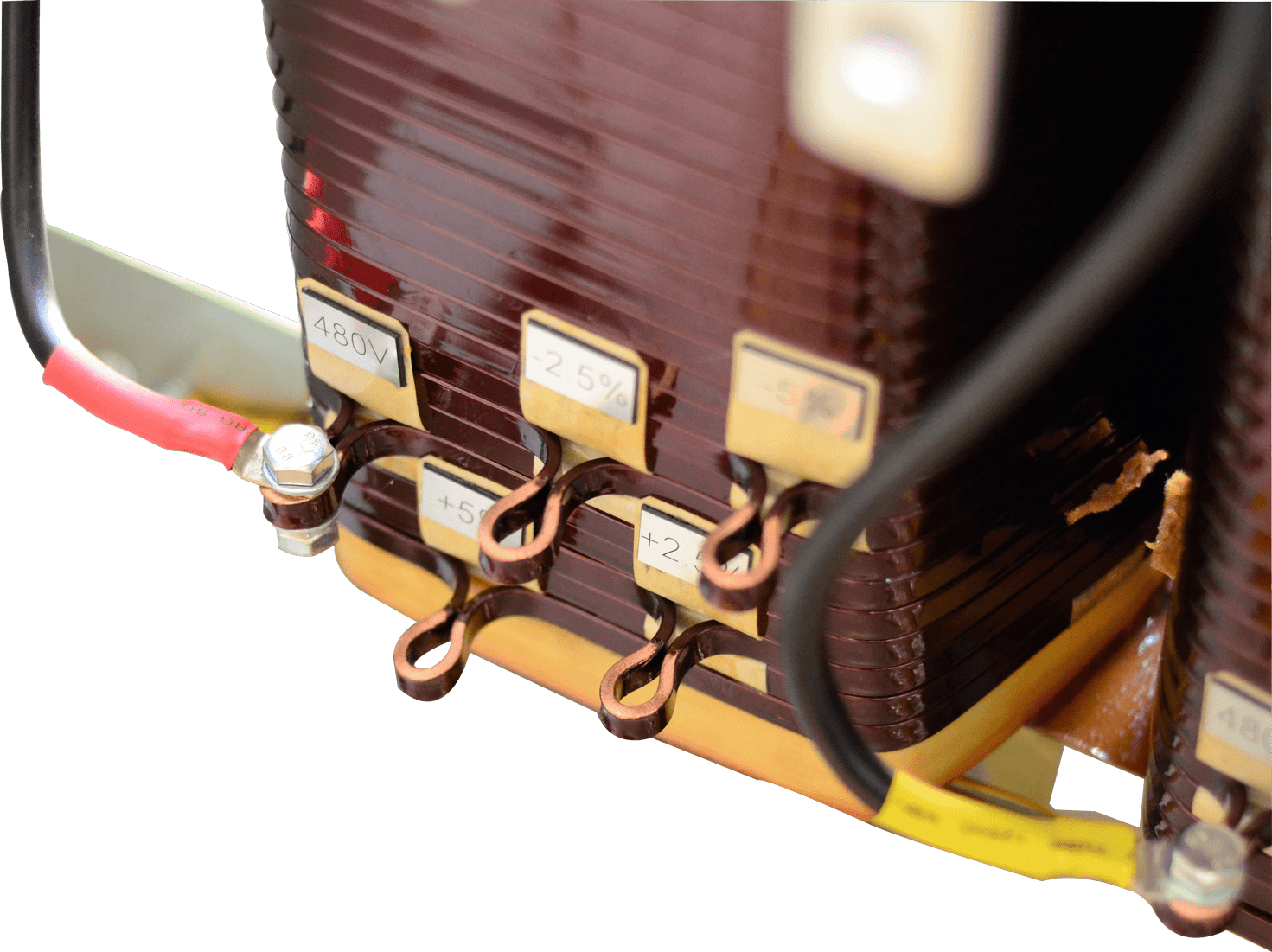

- Taps provided on primary to compensate for voltage variations (as optional).

Typical Applications:

All General loads, indoors and outdoors, including lighting, industrial and commercial

- Schools

- Hospitals

- Factories

- Office building

- Housing complex

- Amusement parks